TIRAGE

Stone Hill Winery’s three sparkling wines: Blanc de Blanc, Brut Rosé, and Demi-Sec start out as all still white wines do and then follow the traditional “Methode Champenoise” to become sparklers. Once our sparkling wines are bottled (tirage in French – “the bottling of the wine”), they go straight into wooden crates (tirage bins). Each bin contains 506 bottles. These bins are stored in a temperature controlled cooler to undergo fermentation at 58ºF.

Here you can see the deceased yeast on the bottom of the bottle of our Cuvee Demi-Sec.

This bottle fermentation (which is the secondary fermentation that creates the effervescence inside the bottle) takes about 2 months to complete. Once fermentation is finished, the bottles stay in these crates for up to 3 years to undergo autolysis of the yeast that will help to create more complexities in the wine.

RIDDLING

When we have deemed the aging-sur-lie finished, we start the next process, which is remuage (or riddling). Riddling is done to shift the yeast from the base of the bottle into the neck. Manual remuage takes 4-6 weeks and involves on average 25 turns per bottle. We are fortunate to have a GYROPALLETTE that can riddle 1008 bottles at once. Gyropalettes work 24 hours a day and take a fraction of the time (one week instead of six,) at no expense to

Here you can see the yeast collecting in the neck of the bottle.

quality. The bottle starts in the horizontal position. The GYRO will slowly start tilting the bottles and at the same time incrementally rotate as well, in a clockwise and counter-clockwise direction. This movement will cause the yeast to slide down the glass.

THE DISGORGING PROCESS

Freezing of the neck:

Once the yeast is collected in the neck of the bottle, our next goal is to remove the yeast “plug” without it flocculating back inside the bottle creating a turbid wine. We carefully transfer the bottles in a vertical position, to the NECK FREEZER. This piece of equipment can drive the temperature of this “cold bath” down to -20ºC for rapid freezing of the necks of the sparkling wine bottles. It takes about 10 minutes for the first inch of the bottle to freeze.

Removing the “ice-plug-of-yeast” aka DISGORGEMENT:

The sparkling wine is initially bottled with a crown-cap (a beer cap). This is so we can open the bottle very easily. At this point there is pressure inside the bottle ~ anywhere between 50 and 90 psi ~ due to the secondary fermentation. When the bottles are opened they are going to release the pressure which is what pushes out the inch of frozen wine containing all of the yeast. This is a very quick process and minimal wine or effervescence is lost, largely due to the entire DISGORGING process occurring with the wine and the bottle being cold.

Liqueur de Dosage:

Next the bottles are topped off by adding a little bit of our secret liqueur to each bottle. Depending on our goal, this dosage can help give the sparkling wine a little more complexity and/or fruitiness.

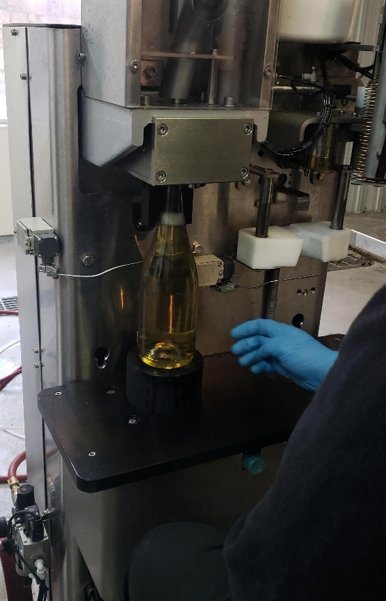

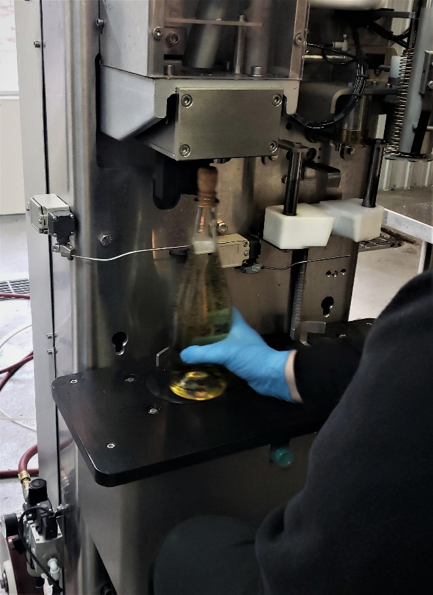

Looking at the image, it shows the bottom bottle getting dosage added. An accurate amount of dosage is injected to each bottle every time. Again, this entire process is done under pressure in a closed bottle so no effervescence is lost.

Corking and a Wire Hood:

In order to ensure that the cork stays in the bottle, since the effervescence can push the cork out, a wire hood is put in place (by hand) to secure the cork inside the bottle.

Violà:

All that is left is to add a label. Sparklings are definitely a labor of love….and we think well worth the effort!